WRS2020 Robotic Assembly Challenge.

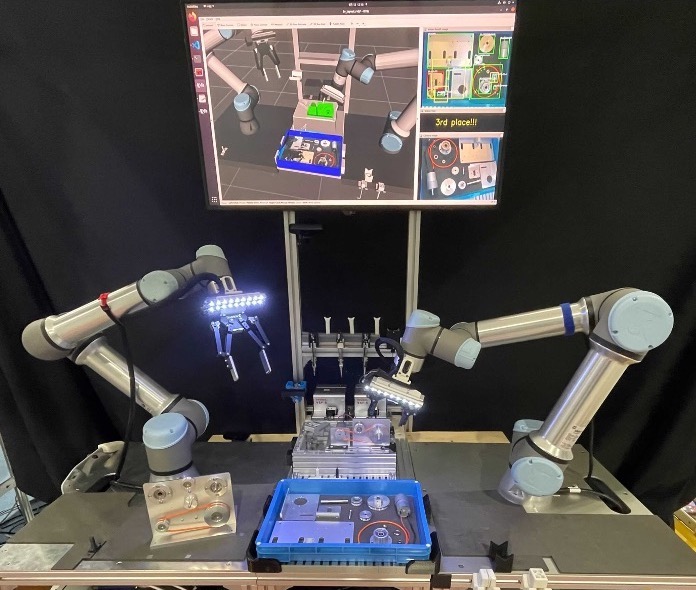

Robotic Industrial Assembly Challenge at WRS2020 World Robot Summit. As part of the O2AC team, we achieve the 3rd place.

I join the competition as part of the O2AC team. I participated as a Ph.D student at Osaka University in the Robotic Manipulation laboratory and as an intern at OMRON SINIC X.

We achieve 3rd place in the Assembly Challenge and recieve a special award from the Japanese Society of Artifitial Intelligence (JSAI).

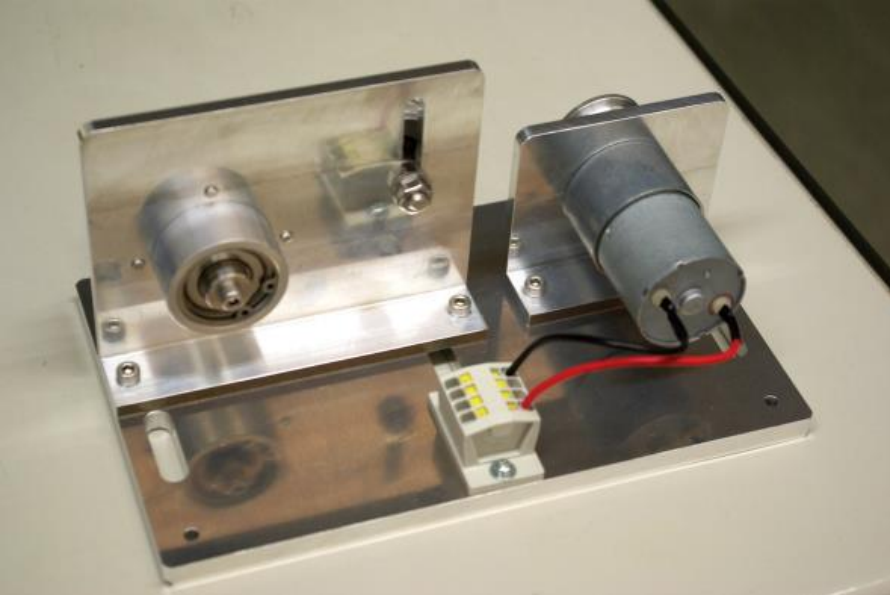

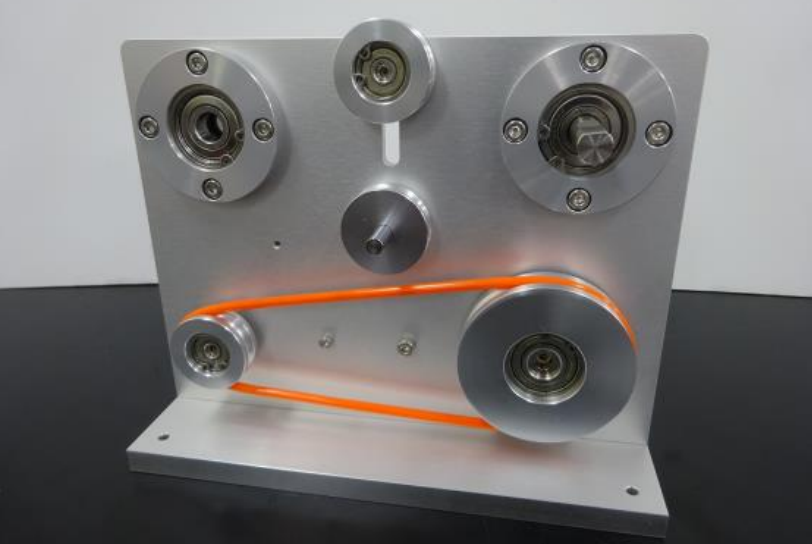

The goal of the competition was to develop a robotic system capable of autonomously performing the precise assembly of two industrial products.

Our solution consist of a dual arm system with the Universal Robots UR5e, parallel grippers, realsense cameras and custom compliant tools.

As the O2AC team, we developed this dual arm system to tackle assembly tasks in a flexible manner with the additional goal of being afforable, cheap vision system hardware and cheap tools.

Our 2-minute team intro video showcasing our approach is here.

See our exhibition talk and demo.

See our completed assembly task of the taskboard here.

Code is available at github.com/o2ac/o2ac-ur.

See out technical paper.

Contributions

I was tasked with the development and implementation of manipulation strategies to complete the precise assembly subtasks for each product. More specifically, I implemented a compliance controller, a simulations trajectory controller on MoveIt, a high-level planner to solve each task, and manipulation strategies to properly orient each part before assembly.

Compliance control

I developed the compliance controller that allowed the robots to perform smooth insertions with tight tolerance s.

Simulateous Trajectory Controller

Additionally, I helped developed a simultaneous trajectory controller on the ROS motion planning library MoveIt (Our implementation has been submitted see here), which allow us to have each robot plan and execute collision-free trajectories simultanously and independently without needing to manually coordinate the motion of both robots.

High-level Planner

Furthermore, I was heavily involved in the development of the high level planner that allow us to solve assembly task based on the CAD model information of the product and its parts. Within this planner I developed several manipulation strategies to orient and align the components using the environment geometry constraints and handover for the assembly process.